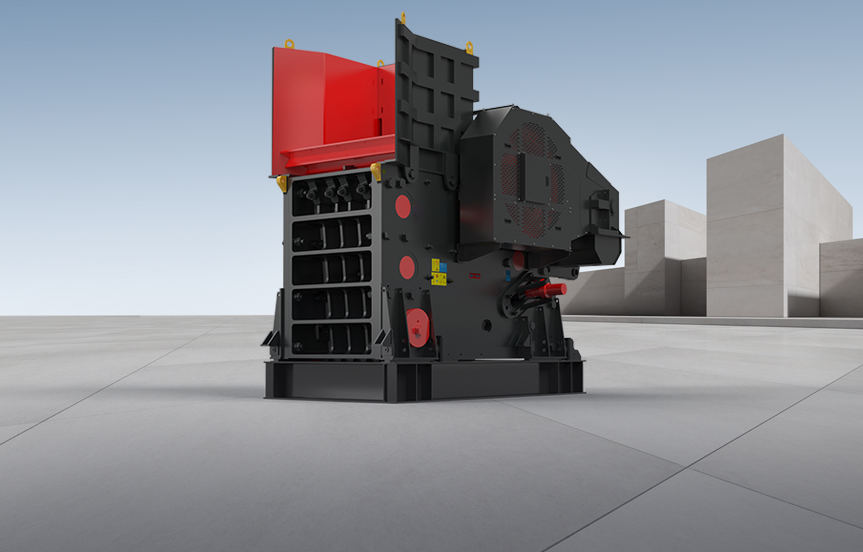

The stone crushing plant is generally composed of jaw crusher, impact crusher, cone crusher, hammer crusher, mobile crushing station, and so on. They are widely used in the mine, metallurgy, building materials, highway, railway, water irrigation, and chemical industry. They have the features: big crushing ratio, even granularity, simple structure, reliable working condition, convenient repair, and economical operation.